Plato 3 MPI Conveyor Unit

CASE STUDY: Plato 3 MPI Conveyor Unit

Introduction

The Johnson & Allen Plato 3 MPI Conveyor Unit is a fully bespoke MPI bench unit conceived, designed and manufactured at our Engineering site in Sheffield, UK. Many decades of industry experience went into producing this unit which showcases Johnson & Allen’s expertise in both electrical and mechanical design, manufacturing and a deep understanding of NDT fundamentals.

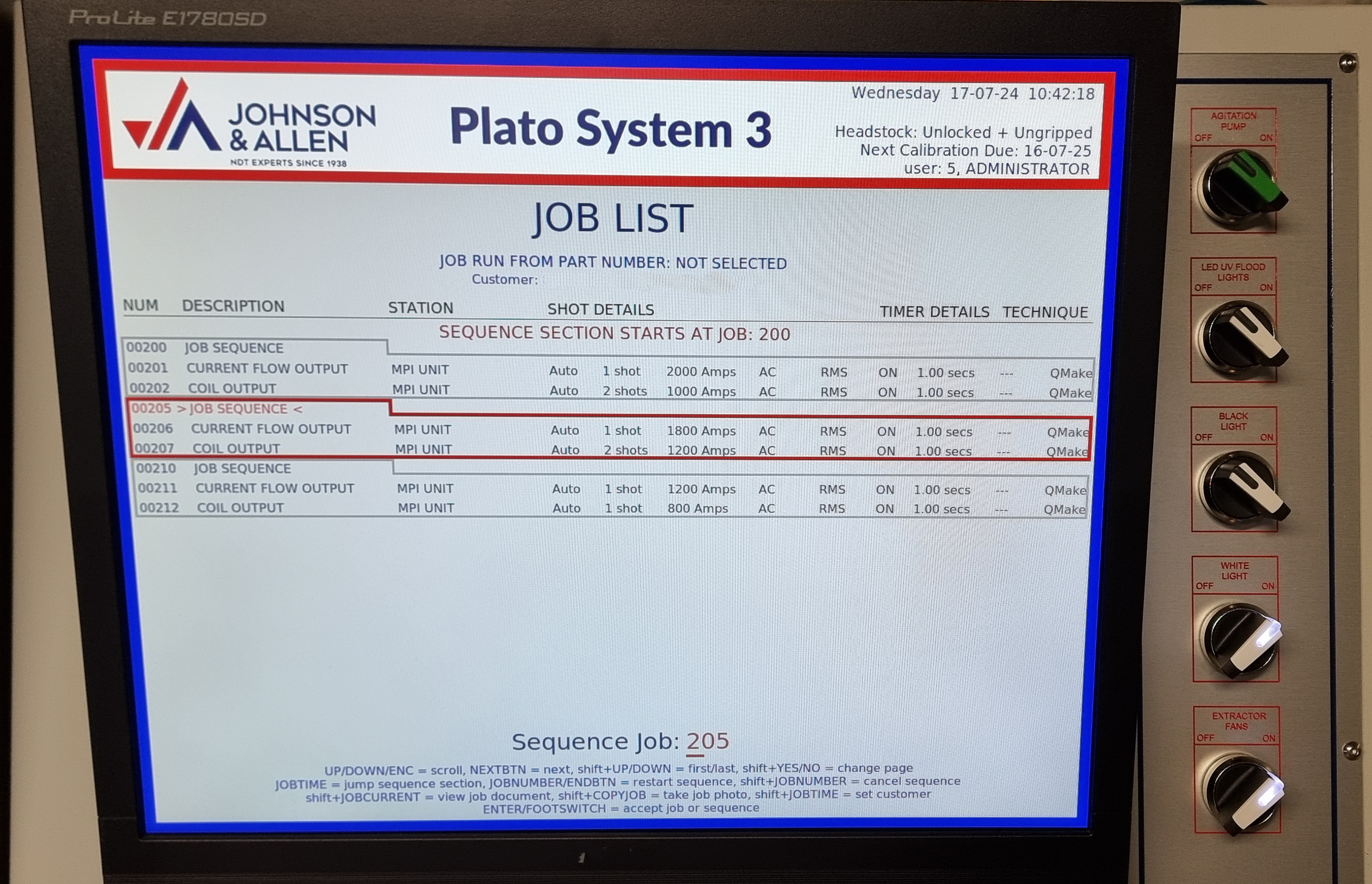

Designed around Johnson & Allen’s latest generation of MPI interface and current control system, the Plato 3 System allows amperage pre-selection (sometimes called ‘dial-an-amp’) as well as the ability to create job sequences (sometimes called recipes), load these job sequences using QR / barcodes and enables different user access levels with inspection logging features. This project then combines the Plato 3 System with a level of automation to streamline the inspection process - The result is a bespoke NDT solution that exceeds all customer requirements.

Johnson & Allen’s advise to customers is – “Do not settle for second best because of manufacturer inflexibility”

If your organisation has unique requirements then do not compromise on them - Discuss them with Johnson & Allen.

The below case study is general summary of the project from initial conception, through to design and manufacture.

Note that some project information is omitted for customer confidentiality.

Concept and Improvement

Johnson & Allen’s technical sales team visited the customer to discuss their requirements and see the proposed area.

The overview was that the customer was looking to replace an existing unit that was showing signs of age. With an increasing number of components on their older unit being discontinued and becoming unsupported, there was a growing concern that a major breakdown would have had a knock on effect to other processes in their plant and cause significant disruption in their wider organisation.

Johnson & Allen also suggested additional improvements to the features already present, which included the benefits from upgrading to the Plato 3 System and more maintenance features – The final design would need to allow for easier personnel access and more options when isolating processes for setup, maintenance and diagnostics.

Choosing the right NDT techniques

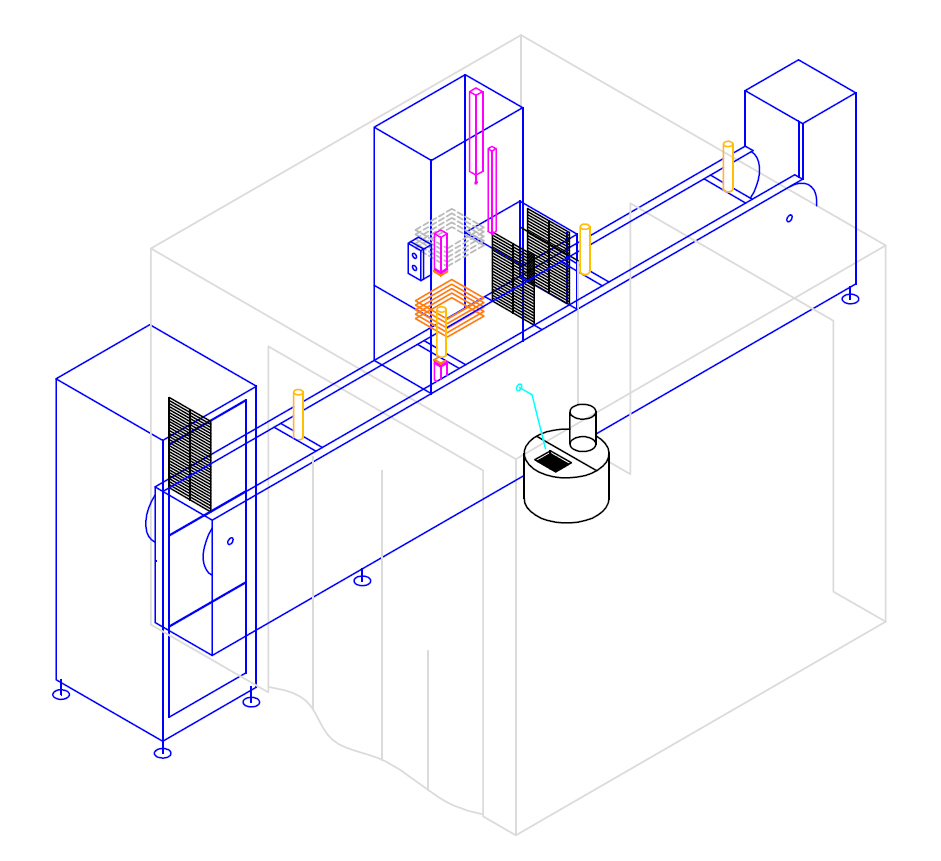

The Plato 3 MPI Conveyer Unit was designed to integrate into a larger processing line. This would be a fluorescent MPI process where parts were to be loaded on a jig and brought into the MPI area using the conveyer, inked and energized and then inspected by an operator in a blackout booth.

"AC waveforms give the highest level of detection clarity for surface breaking defects"

Because the customer was only looking for surface breaking defects with MPI, the unit was designed for AC modes of output which give the highest level of detection clarity for defects of this type. However had the customer had wanted sub-surface capability HWDC and FWDC output modes would have been an option.

The geometry of the parts, the required throughput and the floor space available lent themselves towards a vertical wet bench configuration. In layman’s terms - Parts would receive a current flow shot through them vertically for finding longitudinal orientated defects, then receive a coil shot for finding circumferential orientated defects. This is a very similar process to how a more typical horizontal wet bench would operate, just rotated through 90 degrees (hence vertical wet bench).

Developing the Proposal

The conveyer, entry doors, contact clamping, inking sequence, energizing sequence including the coil movement were all designed to be automated. While the framework and all panels were to be 304 stainless steel, most suited for the environment the unit was intended for and to maximise the lifespan of the system.

At this stage Johnson & Allen then provided the customer with a detailed technical quotation and concept plan for consideration. After a couple more meetings with the customer to review and discuss build options, Johnson & Allen was happy to receive confirmation it had won the contract - And with the design concept approved the build could commence!

Design / Manufacture

With the project launched Johnson & Allen began to source materials while developing the technical drawings, turning them from concept drawings to work drawings for our fabricators and electricians.

Different aspects of the unit were worked on in parallel where possible – While the frame and conveyer were being built, control boxes were being wired and the transformers were being wound by different teams within Johnson & Allen. Unlike other NDT equipment manufacturers, Johnson & Allen keep as many processes in-house to ensure quality and product support for the longest period in the industry.

During the build period we welcomed the customer in to see progress and discuss any further considerations or preferences they had. As the unit was manufactured entirely in-house any minor adjustments they requested we incorporated into the design as part of the build process.

Other features included the 50 litre ink hopper which is sited at the front of the unit for ease of access when undertaking daily solid content measurements and replenishing particles - With the aforementioned Plato 3 System giving operators an on screen reminder to do these checks as well, reducing the possibility of operator errors. The Plato 3 System shows the selected technique sequence and current values on a display which can be dimmed during inspection to minimise background white light for NDT standards compliance.

A handheld Neo-V-365 Inspection Lamp and two Titan UV-A floodlights were also included in the build to ensure high intensity UV-A lighting conditions for the inspection. With low level background UV being provided by the lighting in the blackout booth ceiling. For operator comfort exhaust fans also feature to remove odours and minimise heat build-up.

Using Johnson & Allen's in-house UKAS calibration services (4168) the unit was calibrated and the certificates supplied with the operator manuals as standard.

With the unit completed the customer was once again invited in for Factory Acceptance Tests (FAT’s) at our Sheffield based Engineering site. The customer brought part(s) with known defects as one of their acceptance tests and confirmed adequate field strength was generated with a gauss meter. With the FAT’s passed the unit was packed and delivered to site with safe offloading overseen by a representative from Johnson & Allen.

Commissioning

The customer prepared the relevant services prior to commissioning to ensure that a suitably rated 3 phase electrical supply and clean dry air feed was local to where the Plato 3 MPI Conveyor Unit was to be sited.

The unit was first positioned, levelled and then bolted down before being connected. With the blackout booth assembled, the unit was then powered on and tested again.

Following this a comprehensive schedule of training was provided as part of the proposal to ensure the operators and site maintenance knew how to safely operate the unit. Finally the unit was signed off as part of the Site Acceptance Tests (SAT’s) with production to resume the following working day.

In total the schedule of installation, commissioning and training took around 5 days for this build, with the customer having peace of mind knowing that they have same day technical support available if they ever need it in the future.

After Thoughts

This is just one case study of many projects Johnson & Allen has completed over the last 85 years in business - However the Plato 3 MPI Conveyor Unit will no doubt remain a memorable one because it is so bespoke.

With regular maintenance the Plato 3 MPI Conveyor Unit is expected to be in use daily for at least the next 20 years! Within which time the unit is expected to inspect many thousands of parts and be a vital part of their production and quality process and ensure the parts are defect free.

“We would like to thank our customer again for choosing Johnson & Allen for this project; Every project we undertake is important to us but their team has been pleasure to work with”

– Simon Johnson (J&A Director)